On a recent December day, Mark Latino and a handful of his workers spun sheets of vinyl into tinsel for Christmas tree branches. They worked on a custom-made machine that’s nearly a century old, churning out strands of bright silver tinsel along its 35-foot (10-meter) length.

Latino is the CEO of Lee Display, a Fairfield, California-based company that his great-grandfather founded in 1902. Back then, it specialized in handmade velvet and silk flowers for hats. Now, it’s one of the only companies in the United States that still makes artificial Christmas trees, producing around 10,000 each year.

Tariffs and Trees

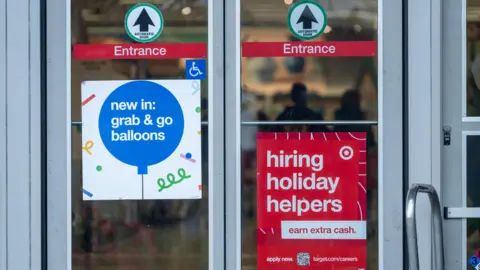

Tariffs shone a twinkling light this year on fake Christmas trees, highlighting the extent to which America depends on other countries for its plastic fir trees. Prices for fake trees rose 10% to 15% this year due to new import taxes, according to the American Christmas Tree Association. Tree sellers cut their orders and paid higher tariffs for the stock they brought in.

Despite these challenges, tree companies say they aren’t likely to shift large-scale production back to the U.S. after decades in Asia. Fake trees are labor-intensive and require components that the U.S. doesn’t make, said Chris Butler, CEO of the National Tree Co., which sells over a million artificial trees each year. Americans are very price-sensitive when it comes to holiday décor. Butler commented, Putting a ‘Made in the U.S.A.’ sticker on the box won’t do any good if it’s twice as expensive.

About 80% of U.S. residents who put up a Christmas tree planned to use a fake one this year, according to the American Christmas Tree Association, and this preference hasn’t changed for at least 15 years. Mac Harman, the founder and CEO of Balsam Brands, pointed out that many people prefer artificial trees because they can set them up on Thanksgiving and keep them for weeks, something not possible with fresh-cut trees.

Labor-Intensive Work

It takes an hour or two to make an artificial Christmas tree, from molding the needles to attaching lights. Workers in China, where 90% of fake trees are made, earn $1.50 to $2 per hour. Balsam Brands, based in Redwood City, California, looked into U.S. production when tariffs were threatened but discovered that the American-made trees would cost far more – a tree that sells for $800 would cost $3,000 if manufactured in the U.S.

Lee Display employs three or four people for most of the year, adding more during the holiday rush for installations and displays. Latino appreciates the ability to produce orders quickly and maintain control over their quality and timing.

Companies are exploring options to diversify their sourcing. National Tree Co. moved some manufacturing to Cambodia and aims to reduce its reliance on Chinese suppliers. Still, increased tariffs on imports have forced many companies to make cuts to their workforce or freeze raises.

Balsam Brands reported a decrease in U.S. sales by 5% to 10% this year, while sales in Germany, Canada, Australia, and France were up, indicating the challenges posed by tariffs. If a merry Christmas is measured by decorations put up, it’s going to be a slightly less merry Christmas, Harman reflected.